Aftermarket Excavator Parts vs. OEM: Which is Better?

Aftermarket Excavator Parts vs. OEM: Which is Better?

Blog Article

Vital Tips for Choosing Aftermarket Excavator Components for Building And Construction Projects

When it comes to construction projects, the option of aftermarket excavator components plays a critical duty in ensuring the smooth procedure and durability of heavy machinery. From compatibility and high quality guarantee to prices factors to consider and provider credibility, there are essential variables to consider when selecting aftermarket excavator parts.

Importance of Compatibility

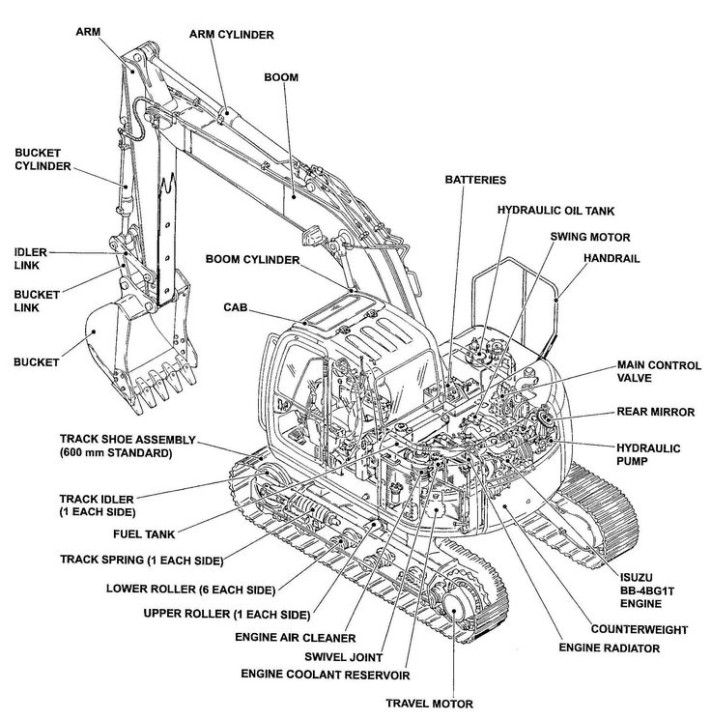

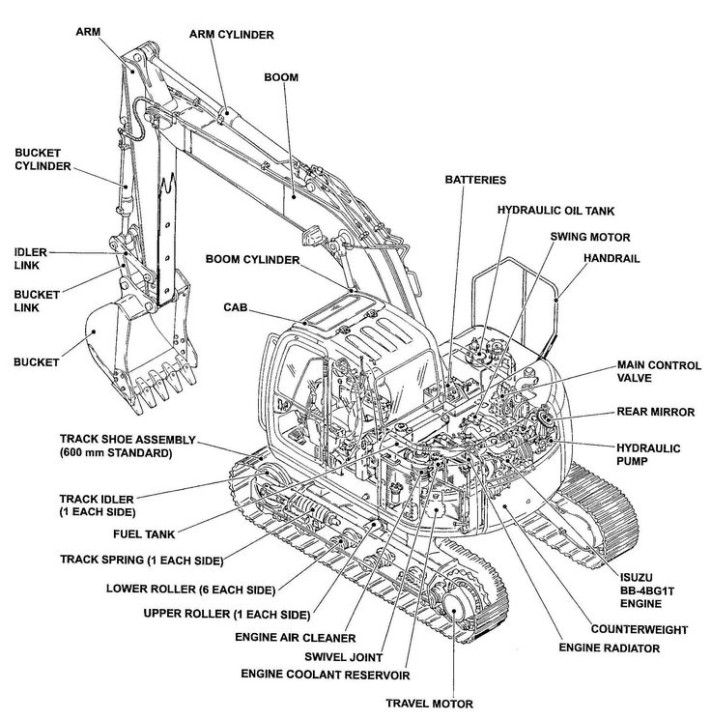

Making sure compatibility in between aftermarket excavator parts and the certain make and version of the machine is essential for ideal efficiency and long life. Making use of components that are not developed for a particular excavator can lead to inefficiencies, malfunctions, and even serious damages to the tools. Producers designer excavators with details specs and resistances, and making use of aftermarket parts that do not satisfy these demands can jeopardize the maker's performance.

To stay clear of these issues, it is vital to work with reputable suppliers that provide aftermarket components specifically designed for the make and model of the excavator concerned (aftermarket excavator parts). Prioritizing compatibility will aid take full advantage of the excavator's performance, enhance its life expectancy, and eventually save money and time on repair work and replacements

Top Quality Guarantee

Compatibility between aftermarket excavator parts and the details make and design of the machine is essential for optimum performance and long life, highlighting the importance of strenuous quality control measures. Quality control in aftermarket excavator components entails stringent screening procedures to ensure that the elements meet or surpass market criteria. This includes material top quality checks, dimensional precision analyses, and performance testing under numerous operational conditions.

By executing durable quality control protocols, suppliers can guarantee the integrity and resilience of their aftermarket excavator parts. Consumers take advantage of this guarantee as it minimizes the risk of early component failure, costly repair services, and task delays. Adherence to quality requirements boosts the overall security of construction sites by minimizing the probability of tools malfunctions.

Buying aftermarket excavator parts that have gone through detailed top quality guarantee treatments gives construction companies with self-confidence in the integrity of their devices. It additionally reflects a dedication to supplying top quality results successfully and successfully on project sites.

Pricing Factors To Consider

With cost-effectiveness being a critical element in procurement browse this site decisions, evaluating the prices of aftermarket excavator parts is crucial for making best use of worth in equipment maintenance and repair service. When thinking about pricing for aftermarket excavator components, it is critical to strike an equilibrium in between expense and top quality. It is advisable to perform complete study on the prices of numerous aftermarket components, contrasting aspects such as supplier, resilience, and warranty track record.

Guarantee and Return Policies

Furthermore, a clear and reasonable return plan is essential in instance the purchased components are not suitable or experience issues. aftermarket excavator parts. Customers ought to understand the return process, including any kind of restocking fees or return shipping prices they might sustain. An easy return plan shows that the vendor is certain in their products and values customer experience

Supplier Online Reputation

Having a strong credibility in the sector is vital for aftermarket excavator components distributors to build depend on with customers and develop reputation in the market. A supplier's online reputation is a representation of their dependability, product quality, client service, and general efficiency. When selecting aftermarket excavator parts, it is essential to think about the online reputation of the vendor to ensure that you are obtaining top notch items and outstanding assistance.

One means to evaluate a supplier's reputation is by looking into client evaluations and testimonies. Comments from previous customers can offer beneficial insights right into the supplier's performance history and the top quality additional reading of their products. In addition, you can also inspect industry discussion forums, web sites, and social media sites systems to see what others are claiming regarding the vendor.

One more element to consider is the provider's experience and longevity on the market. Established vendors with years of experience are more probable to have a solid reputation compared to newer entrants. By choosing a trustworthy supplier for your aftermarket excavator components, you blog can improve the success of your building and construction projects and make sure the longevity of your tools.

Verdict

To conclude, when picking aftermarket excavator components for building jobs, it is vital to prioritize compatibility, quality control, pricing factors to consider, service warranty and return plans, in addition to provider online reputation. Making certain that the components are suitable with the certain excavator version, are of premium quality, fairly valued, backed by a guarantee, and sourced from trustworthy providers will add to the success and effectiveness of the building project.

From compatibility and quality assurance to rates considerations and provider credibility, there are vital elements to think about when selecting aftermarket excavator parts.Compatibility in between aftermarket excavator components and the specific make and version of the equipment is crucial for optimum performance and long life, emphasizing the relevance of extensive quality guarantee steps. Quality guarantee in aftermarket excavator components entails rigid testing procedures to guarantee that the components meet or go beyond sector criteria. aftermarket excavator parts. When selecting aftermarket excavator parts, it is vital to consider the online reputation of the provider to ensure that you are getting high-quality products and outstanding support

By picking a respectable provider for your aftermarket excavator components, you can boost the success of your building jobs and ensure the durability of your devices.

Report this page